The Inventory & Stock Control Lever of eCommerce Efficiency

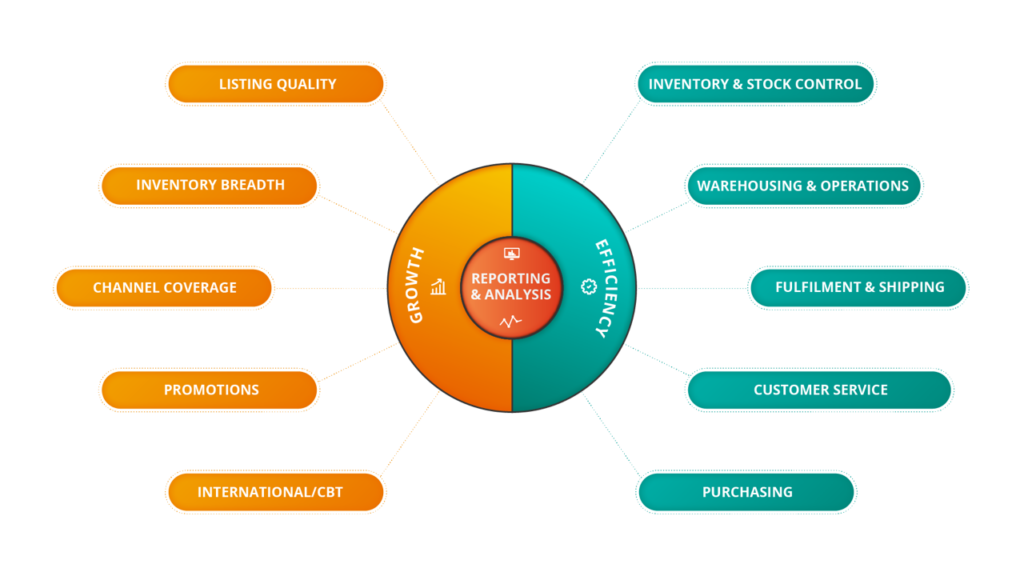

A good few posts ago we introduced our concept of the Levers framework as a checklist for strategising on and executing the various levers at your disposal to develop your ecommerce business. We’ve already devoted a post to each of the 5 growth levers, the ‘yin’ if you like. In this post we talk about the first of the ‘yang’ levers, which help improve your efficiency. This post is about inventory & stock, and how best to control it across your multichannel business, using marketplaces like Amazon, eBay and OnBuy, as well as webstore platforms like Magento and Shopify.

To increase your revenues (assuming you have good listings, prices and shipping for your products), you could increase the breadth of inventory on offer and make the inventory you have, ‘virtual’ or otherwise, available in more places. But what about the cost side of the equation? The more inventory you have, the more time, effort and money it takes to manage it. The more places you sell stock in, the more places you have to update the stock levels. It’s a largely proportional relationship, where more stock means more operational overhead. With each sale you still have to rebalance the stock levels wherever you’re offering the products.

Let’s look at some of the factors affecting this lever. Firstly, if your processes are mainly manual, then you need a lot of work to keep tabs on everything. If you sell in one place, then this is manageable with manual processes. Many Volo customers find that the addition of a second place, if they don’t have their own website, becomes the tipping point. They won’t easily be able to use spreadsheets or paper to follow the flow of goods. They have to move from manual to automated.

Secondly, complexity can increase your business processes significantly with the addition of inventory and outlets for your products. This is especially true if a business grows organically rather than with an emphasis on planning and control. Complexity and success sometimes don’t go together because the propensity for costly mistakes increases. The answer here is to look for solutions to help simplify things by streamlining processes and reducing interdependencies.

Thirdly, staffing costs associated with inventory and stock control can also start to rise. You could throw money at the problem and hire more people to manage the problem away. This will give you accuracy and peace of mind until you calculate how your cost base has increased. It will also have corresponding effects on your precious operating margins and profits. Can you raise your prices and risk becoming uncompetitive? Again, the solution is to get the right balance between automation and human hands on deck.

Fourthly, there’s what the finance people call the time value of money. The more time it’s taking you and your staff to stay on top of your inventory and stock movements, the more it’s costing you. If your business is subject to seasonality variations, then these costs will peak and trough over the course of the year and you will need to plan for them. If your people can’t update stock levels fast enough across all your marketplaces, you risk overselling your fast-moving items. You’ll also disappoint your customers and see your seller ratings go down. Finally, you could potentially be removed from a channel.

Fifthly, it can sometimes be very difficult to get a true picture of what’s happening in your business. If you’ve ever tried to walk or drive briefly with your eyes closed, you’ll remember that feeling of disorientation and high anxiety. It can be a similar feeling with your business. Problems await the company without accurate and current information on inventory and stock levels. You also need to take into account sales performance across your products. Lack of visibility across your online channels, in the form of detailed data, can make it hard to make good, confident decisions.

So, what to do about all this? Our role at Volo is to provide you with the systems and advice you need to increase your effectiveness in this important area. Over the years, together with our customers we’ve accumulated a range of best practices on the subject, covering listing, data, stock levels and pricing. It’s very hard to address any of these areas if you don’t have the right information on which you base your decisions, so our approach is to help our customers get visibility into their stock movements. In our dealings with them, and for the rest of this post, we lean on our ecommerce analytics package which is called Vision.

You need decent analysis and reporting so that you’re not paralysed by not enough information, or too much of the stuff which makes it inaccessible. As you might imagine, multichannel ecommerce systems like Volo come with detailed reporting that allows you to easily analyse where you’re at and provide you with alerts to certain stock situations. Here is a sample of the areas that can help you improve your inventory and stock control.

It’s about dead stock, slow-moving stock or no stock, all of which are bad since they’re either tying up cash in your business or not bringing any cash in. What stock hasn’t moved and what stock is moving too slowly? Dead stock and slow moving stock reports identify stock that’s no longer selling (or has never sold) and stock whose velocity is showing a downward trend. This enables you to make decisions on stock disposal or construct special offers to shift the products, thereby improving cash flow.

With zero stock you want to know as soon as possible how many days you are all out of key SKUs. Stock outs are especially a problem for your items that sell well, since this means that you’re losing a key portion of your sales. Narrow down your analysis to individual SKU or variation SKU items. After this, you can make decisions on whether you re-order the inventory or discontinue offering it.

An early warning system always helps. First, factor in both the speed your items are selling (and how many days’ stock of a product you have left) as well as the amount of time it takes your supplier to deliver new inventory. Then you can forecast stock availability and have a traffic light system or configure alerts to remind you when items get down to a certain level and need to be re-ordered at current or recent sales velocity. This is a big time-saver for you, as it frees you up from looking at figures all day to run the other areas of your business.

It goes without saying that you should keep your best sellers and your most profitable items well stocked, if you possibly can. Do you know your best sellers by value, volume or both? Can you evaluate which SKUs are making the biggest contribution to your profit? Focus on keeping the best sellers and the most profitable inventory constantly in stock, since these are closely tied to your cash conversion cycle and your bottom line. Again, sales velocity and order lead times are key variables to understand, unless you have a system to do it for you.

How much should you re-order? Keeping control of your inventory and stock costs is also about having the right amount of the good stuff, stuff which you can move in and out of your business and convert to cash as quickly and efficiently as possible. You gotta do the analysis, and speed is king as we’ve said, since it determines how many days coverage you have at prevailing rates before you run out, and in turn the re-order quantity.

When you have accurate stock information and the right stock levels for the relative speeds your products are moving, you increase your efficiency. We help companies reduce costs through streamlined inventory processes and the automated processing of reliable supplier feeds. Paul Lever, Director of appliances merchant Cheapest Electrical uses the Volo system to manage its inventory and stock control and estimates the system saves it between 3 and 4 staff a year: “Volo is big boys’ software which allows us to list our entire stock on various multichannel platforms and keep a close control.

To talk with us about the inventory & stock control lever and the other efficiency levers in your own business, please send us a note here.